TVR Chassis Restoration

TVR chassis suffer badly from corrosion yet many owners are blissfully unaware as their cars can look pristine above. Chassis suffer mainly along the outrigger tubes and wishbones, which get hammered by road debris thrown up from the wheels. Also in the engine bay the top chassis tubes lose their coating due to heat from the exhaust manifolds and then corrode. Due to the nature of TVR’s powder coating, once it is damaged water creeps behind the coating and corrodes the metal underneath, very often the coating can look intact until it is scraped off to find extensive corrosion damage.

Any chassis corrosion needs to be tackled ASAP before it spreads beyond visible areas above the outrigger tubes and before tubes become corroded beyond repair and need replacement.

Our Chassis Repair Process

If your chassis is in good condition with only minor surface rust we can treat this by removing damaged coatings and corrosion back to bare metal. We then apply Hydrate 80 which chemically converts any rust and forms a protective barrier. This is followed with a high zinc content primer followed by several coats of 2 pack paint and finally a coat of protective stone chip paint.

When the corrosion has gone too far we offer either complete outrigger replacement or, if necessary, a full body off restoration of your existing chassis. Alternatively we can supply and fit a complete new chassis for your Griffith or Chimaera.

We offer a free initial inspection and are happy to discuss and show you any areas of your car that may need attention. (Please note that all prices are plus VAT.)

Outriggers

For Griffith and Chimaera models, having our own chassis jig led us to develop our pioneering system of replacing chassis outriggers with the body in situ. We fabricate complete side outrigger sections from the jig and can then repair your car by replacing the outrigger with the body in-situ. The new outriggers are welded on to your Griffith or Chimaera where they meet the main chassis beams. We do not have to lift the body at all or cut any part of the body to gain access to weld. Note that this method is not to be confused with any kind of “half-outrigger” kit that joins in the middle of the tubes and cannot be fully welded with the body in place.

We cut off the original outrigger section right back at the main chassis beams, we then fit up a new outrigger section bolt it to your body and wishbone pick up points and then fully weld in place. The whole process takes about a week to complete in our workshops or we can supply the outriggers as a kit so that your local TVR specialist can install them for you. We have successfully completed this operation now on over 120 cars and sold over 140 kits to various TVR garages around the country and Europe.

We currently have 5 other TVR Heritage network specialists fitting our outrigger kits so if you can’t make it to us we can put you in touch with a TVR specialist closer to you for the work.

Our outriggers now come finished in a 3 stage powder coat that includes 2 coats of expoxy zinc rich primer.

Outrigger Kit (includes fitting kit): £1100

Outriggers supplied and fitted: £2200

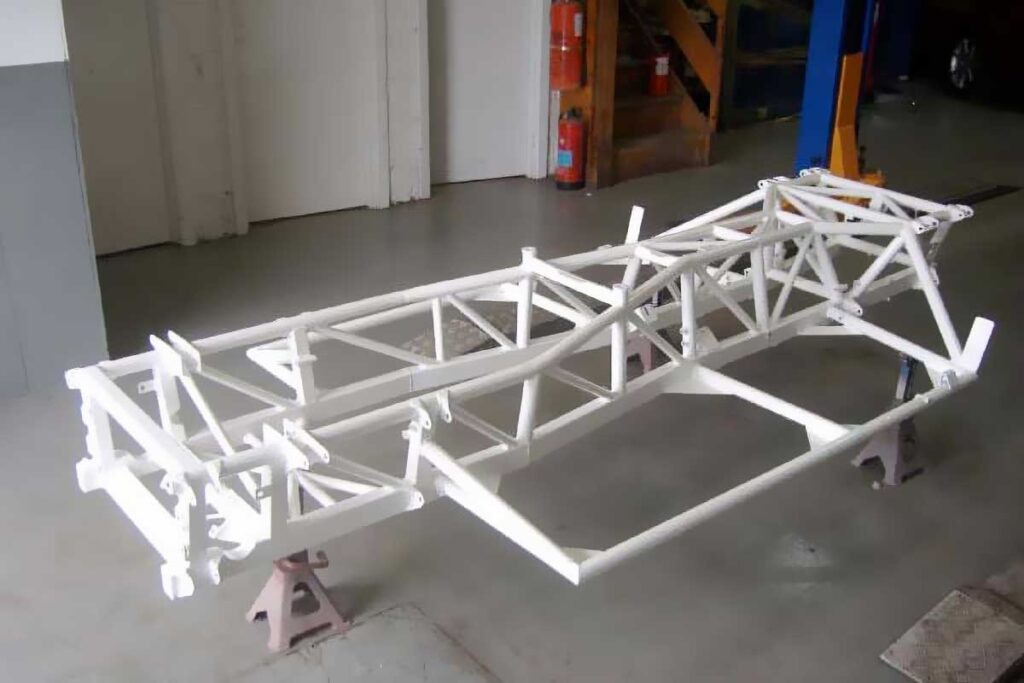

New Standard Chassis

We are proud to offer our brand new standard chassis for the TVR Griffith and Chimaera. We have invested heavily in the production of our chassis jig which has been developed using 3 examples of chassis from different ages of cars, an early 1992 chassis, a 1996 chassis and finally a late 1999 chassis allowing us to make a chassis to match your car’s gearbox and diff configuration.

We can now produce a dimensionally correct chassis to the very latest TVR design with improved and strengthened wishbone pick up points and diff mounts plus some of our own improvements using better quality and better grade of materials than the original.

Chassis are made to order and can be supplied for early cars with Rover gearboxes and GKN diffs or the later T5 gearbox BTR diff cars in RHD or LHD. Our chassis’ are properly cleaned and sandblasted before being coated with a 3 stage powder coat that includes 2 coats of expoxy zinc rich primer in any RAL colour. Production usually takes around 6 weeks. Chassis can also be produced using CDS tube for the round tube sections rather than the usual seamed tube thereby giving greater strength & rigidity.

Price: £5,800 + VAT

TVR Rebuild on Original or New Chassis

We can rebuild your car using your existing chassis. This is fully stripped and sand blasted, new outriggers are fitted and any corroded steel sections replaced. All this is done in our chassis jig. The chassis is then re-coated in a 3 stage powder coat that includes 2 coats of expoxy zinc rich primer and gloss powder coat top coat in any RAL colour.

Alternatively, you can choose to rebuild your car using our brand new standard chassis. In both cases, this is a complete drive-in/drive-out service using your existing body, engine, gearbox, diff and driveshafts. The price includes all of the components listed below.

- New wishbones

- Reconditioned uprights

- New wheel bearings and ball joints

- New brake, clutch and fuel lines

- New handbrake cable

- New fuel pump and filter

- New engine and gearbox mounts

- A choice of new Powerflex or standard bushes

- Nitron or Bilstein dampers and springs

- Rebuilt steering rack

- New discs and pads and reconditioned calipers

Existing G/C Chassis Repair and Rebuild from: £12000 + VAT

Brand New G/C Chassis Rebuild from: £16500 + VAT

TVR Chassis Enquiry

Please tell us about your car and chassis repair requirements and we’ll be in touch.